Losses in quality of metal parts with a high surface quality caused by the cleaning process

You have to face high quality losses during the cleaning process and you can’t find a solution?

You’re from the machining technology, the electrical engineering, the medical technology, the automotive industry or the sheet metal working? You are a manufacturer of metal parts with a high surface quality, sensitive surfaces or metal parts with membranes? You have to face high losses in quality? You have already tested different washing baskets, but the result hasn’t been satisfying? And right now you want to find a solution, so that you can focus on other issues?

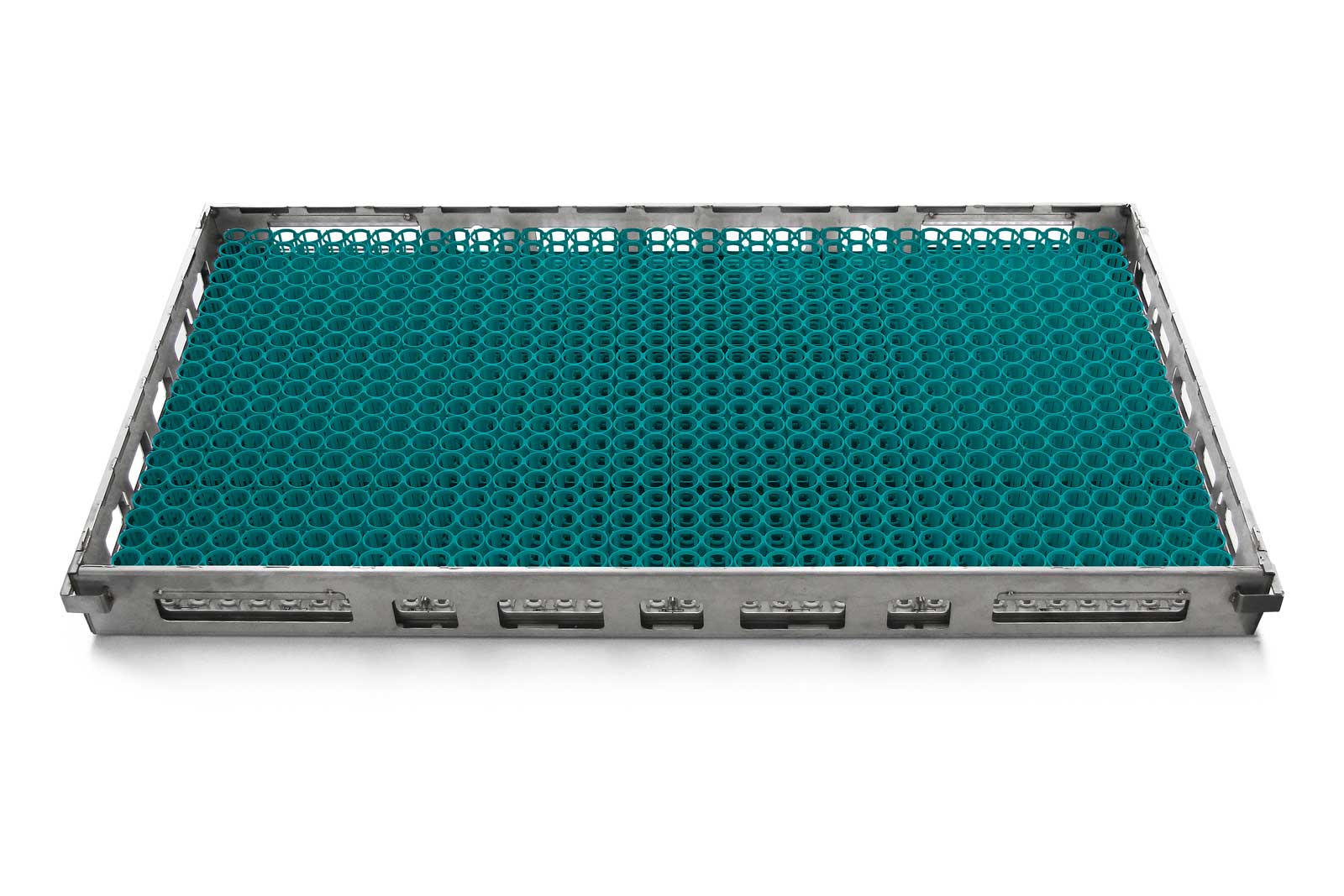

For more than 20 years, we have been developing and producing ALWA smartPINS workpiece carrier systems for highly sensitive metal parts. Through the use of our workpiece carrieres, our costumers have been able to reduce their reject rates drastically, decrease the costs and optimize their processes.

Our customers turned to us with different tasks.

One issue is, that the quality of the cleaning process doesn’t fulfill the demands of the end customer. During the cleaning process, the metal parts weren’t cleaned properly, as within common washing baskets and during the washing not all surfaces can be reached and residues remain.

The second problem often lies in the damage of metal parts with a high surface quality during the cleaning process, caused by the rotation. But this rotation is necessary for ensuring the cleanliness. However the high quality standards of the end costumer fall by the wayside by using common washing baskets and processes. But only through this cleaning process and the transportation scratches and defects occur.

With these and other challenges, our customers contacted us and so far everyone has been impressed by the proposed solutions as well as the concepts.

With our smartPINS you will be given a plus of safety through the shape of the Pins and the quality of the workpiece carrier. The coordinated part geometry of the pins allows even picking up rotationally symmetric as well as asymmetrical products precisely. Neither during the cleaning process or the transportation nor the storage, nothing is shaky or loose.

Even high temperatures within the cleaning process, occurring after the completion of the workpieces, the carrier system can withstand. The quality material is resistant to high temperatures, chemicals, oils and drilling water.

Do you have further questions? Then please contact Klaus Heinzelmann for further information.

Some interesting links: